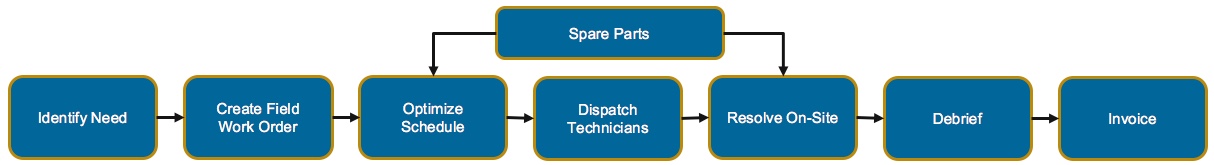

SITUATION:

- Deployed workforces are challenging to control, let alone optimize

- The cost of a trained technician, truck, inventory, and support services are a significant investment

- In a break-fix environment, multiple visits to are commonly required

- Many companies add brick-and-motor to expand to new geographies

QUESTION:

- What is the value of an additional service call per day?

- What is the value one less mile driven?

- What is the customer service value of a first-call repair?

COMPLICATION:

- Service call changes or delivery route changes add miles and costs

- Parts runs to local stores or side-trips turn into lengthy delays

- Invoicing is delayed, waiting for part and service information

ANSWER:

- Once a deployed workforce is optimized:

- Brick-and-mortar may be reduced

- Higher first-call repair rate and fewer miles are driven

- Invoicing happens near-real-time

FOUR PILLARS OF DEPLOYED WORKFORCE OPTIMIZATION

PLAN AND TRAIN

- Customer segmentation

- Technician availability and skill set

- Contract requirements

- Load Balancing

- Technician Training

TECHNOLOGY

- Work Order and Auto-Invoice

- Drawings/ Illustrations

- Predictive troubleshooting

- Catalog and Content Management

- Part number cross reference

ASSET MANAGEMENT

- Customer’s install base

- Time between Failure

- Preventative Maintenance Schedule

SUPPLY CHAIN

- 3rd Party supply and logistics

- Rolling warehouse management

- Truck inventory optimized for Customer Asset Management